What are graphic overlays?

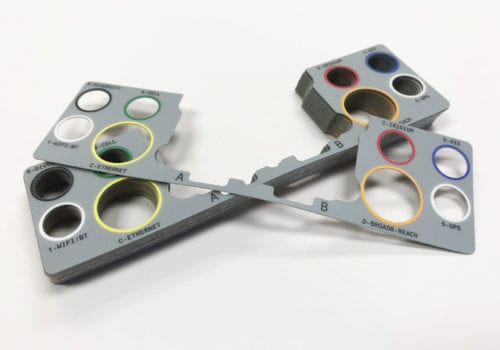

Graphic overlays are thin, durable graphic surfaces that function as the top layer of a product – they’re usually placed on electronics. They serve multiple purposes, including:

- Protecting sensitive internal electronics from wear and tear

- Offering users intuitive guidance on how to operate a device

- Displaying information when necessary – and hiding information when it would be confusing (dead fronting)

- Creating branding opportunities

- Creating a more aesthetically pleasing final product

Applications for graphic overlays

User interface/membrane switch overlay

Graphic overlays are often used to offer guidance to end-users. They can be placed as a graphical top layer for panels containing mechanical switches like buttons and levers.

The overlays can also act as both the guide and the interface – in these circumstances, we would refer to the graphic overlay as a “membrane switch overlay”. These overlays are printed circuits that, when pressed or touched, open or close circuits to trigger functions in electronic devices.

Brand awareness

Graphic overlays double as a marketing tool, improving brand awareness and creating space for logos on the front-facing panel of a device. Overlays come in a wide variety of colors and finishes, and all kinds of different graphics can be printed onto them. Screen printed graphics use U.V. inks, Pantone® colors, or metallic inks. We can accurately match color values, densities, and gloss levels, providing exceptional product color match and production consistency.

Durability

Our overlays are printed on the backside (subsurface) of a clear material like polycarbonate or polyester. These materials are durable and adhere to the final product using various high-quality adhesives. Using a variety of materials from flame-retardant, anti-microbial and even ESD finishes for an explosion proof environment we can meet the needs of your industry. They all help protect sensitive electronics from dust, wear and tear, harsh chemicals, and more.

Dead fronting

Dead fronting is the art and science of using different levels of opaqueness to hide visual elements from sight until those visual elements are illuminated. Think about the “check engine” icon in your vehicle – it’s invisible until the LED is illuminated. That’s achieved through the use of dead fronting.

Industries using graphic overlays

To create an exhaustive list of all the industries that use graphic overlays would be almost impossible. Here are just a few of the many industries and products that use graphic overlays:

- Commercial foodservice

- Commercial refrigeration

- HVAC

- Test and measurement

- Medical electronics

- Portable electronics

- Consumer products

- Agricultural (tractor cabs and farm equipment)

- OEM (Medical)

- Industrial applications

- Laboratory instruments

- Aerospace

- Control panels

- Fitness Equipment

- Telecommunications devices

- Security Systems

Environmental considerations affecting graphic overlay design and material choices

Indoor vs outdoor use

Overlays that are being used indoors will be subject to fewer environmental concerns than those slated for external use. In outdoor use, extreme temperature fluctuations are also a bigger concern. As such, the materials used for outdoor use will tend to be more durable than those used for indoor use and will be designed to withstand shifting due to temperature fluctuations.

In outdoor use, glare can be problematic – we offer anti-glare coatings for our overlays.

Chemicals and abrasion

Consumer electronics will tend to need less resistance to chemicals and abrasion than electronics that are being used in high-stress scenarios. In healthcare, high levels of chemical resistance are essential so the overlay can withstand harsh chemical cleaners. Overlays being used on heavy machinery will need more abrasion resistance. We customize our overlays for their environments. This includes the use of scratch-resistant and chemical-resistant coatings.

Sterile environments

We offer antimicrobial coatings for overlays that are going to be used in healthcare, and our overlays themselves can be built in cleanrooms to ensure sterility.

Heavy usage

Some overlays, like those found in consumer electronics, will be subjected to heavy usage – especially in the case of overlays acting as user interfaces. We can support in designing graphic overlays that are built to withstand repeated or continuous pressure due to heavy usage.

Aesthetic considerations affecting graphic overlay design and material choices

Embossing

Using embossing on your overlay can grant several advantages that are both functional and aesthetic. By embossing, you can highlight which elements of your overlay are most important. Embossing can also be useful to help people with visual impairments find the right buttons on an interface. You’ll also give your final product a unique look and feel – it provides information density and an attractive aesthetic all in one.

Unlimited color choices

Branding is an essential component of practically every graphical overlay. With unlimited color choices, we can create an overlay that perfectly matches your brand with U.V. inks, Pantone® colors, and/or metallic inks. This enables us to accurately match color values, densities, and gloss levels.

These color choices go beyond branding, too. You can highlight important elements of your overlay through the use of contrasting colors.

Special printing effects

We offer a wide variety of different printing effects. These include basic effects like changing the surface finish, to the use of digitally printed graphics for endless customizability.

Backlighting

Backlighting is commonly coupled with graphic overlays so various icons can be toggled on and off. Our overlays can be designed with the use of backlighting and backlit membrane switches in mind. By using techniques like dead fronting, LED windows, and light blockers, we can ensure that your overlay retains its functionality and appearance in conjunction with the use of LED lighting.

Surface finish

At General Label, our overlays come with a wide variety of different surface finishes to match the look and feel you want for your product. These finishes include:

- Gloss

- Velvet

- Matte

- Textured

- Anti-glare

- Soft touch

- Steel